Do's and don'ts

- Details

- Published on Saturday, 19 December 2015 13:23

- Hits: 8904

Here are some remarks on the difficulties I had along the way;

First of all; Make sure to use materials that can stand heat up to over 150 Degrees Celsius. Otherwise it will melt for sure. I did try to use foam and plastics that don't withstand the heat, and it did melt. Mind you, when the solarcollector is in use I have measured temperatures up to the maximum of the sensor very often; The sensor is not measuring over 125 DegC, so it is impossible to tell how hot things get, but it is hot.

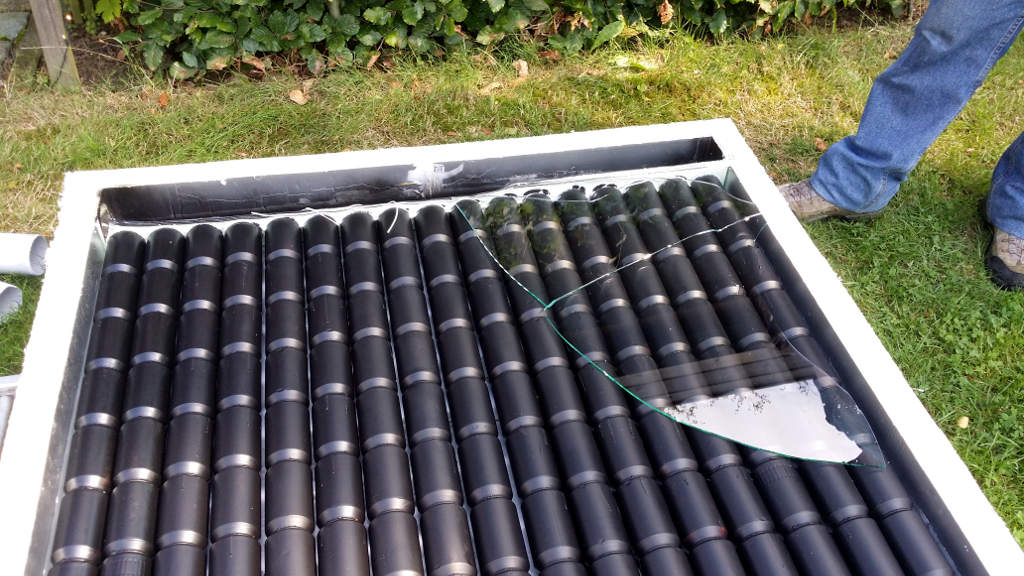

Also don't try to use double glazing; On several attemps with different setups, everytime the glas breaks on the first sunny day, thus making it unusable. Although the return would probably be better with double glazing and therefore better insulation, the glas just isn't strong enough. The best result up to now was by using polycarbonate. But it must be set it is not tested over a full summer yet.

If you do not want to get the collector get too hot, don't start the fan; if the fan is running the output actually becomes hotter then when it doesn't run. If you don't start the fan the collector will get hot to the same temperature everywhere. But if you do start the fan it will get colder at the entrance of the collector and it will get hotter towards the output.

*UPDATE March 2020!*

As it seems, the cans are actually not aluminium in Belgium: It seems they rust! Because of that I had to take the collectors down and replace the cans with some alu-profiles. Basically plates bend in an angle over 90 Degrees, so it captures all sunlight without reflecting it. In the pictures you can see one collector with the cans still, and the other one with the alu-profiles.

To paint I now used very checp sprays, that are normally for stove-pipes. So they can stand the heat up to hundreds of DegC. And that seems to hold well now.

By using the alu-plates, also the use of the glue can be avoided.